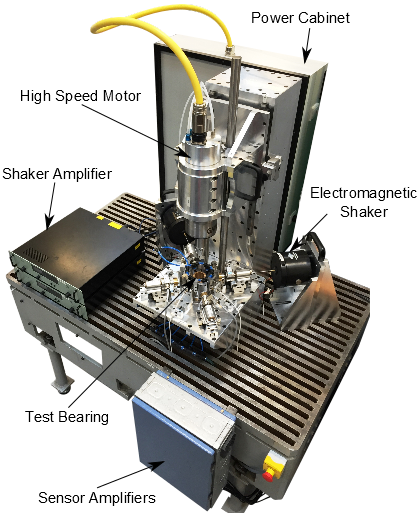

The test rig for experimental investigation and static and dynamic properties of a controllable aerodynamic journal bearing is illustrated in Figure 1. The test facility consists of three main parts: a high speed motor; two electromagnetic shakers and the test bearing. The test rig is designed with the aim of allowing for tests of different bearing sizes, types and configurations, all in industrial scale.

To get insight into the gas bearing dynamic performance the bearing housing will be excited radially in the two orthogonal directions by two electromagnetic shakers, while the rotating disc center is kept in place with no radial movements. The interaction between rotating disc and moving housing will be dictated by the aerodynamic forces, once the clearance (gab) between rotor and stator is kept between 25 and 35 microns. The aerodynamic forces will be strongly dependent on the profile of the bearing clearance. Such a profile can be changed by controlling the smart material properties using current, temperature or magnetism as control input. By adjusting the bearing profile, its static and dynamic properties can be controlled, i.e. load capacity, stiffness and damping.

|

| Gas bearing test facility |